Efficient and eco-friendly cleaning View Our Products

OptiTube

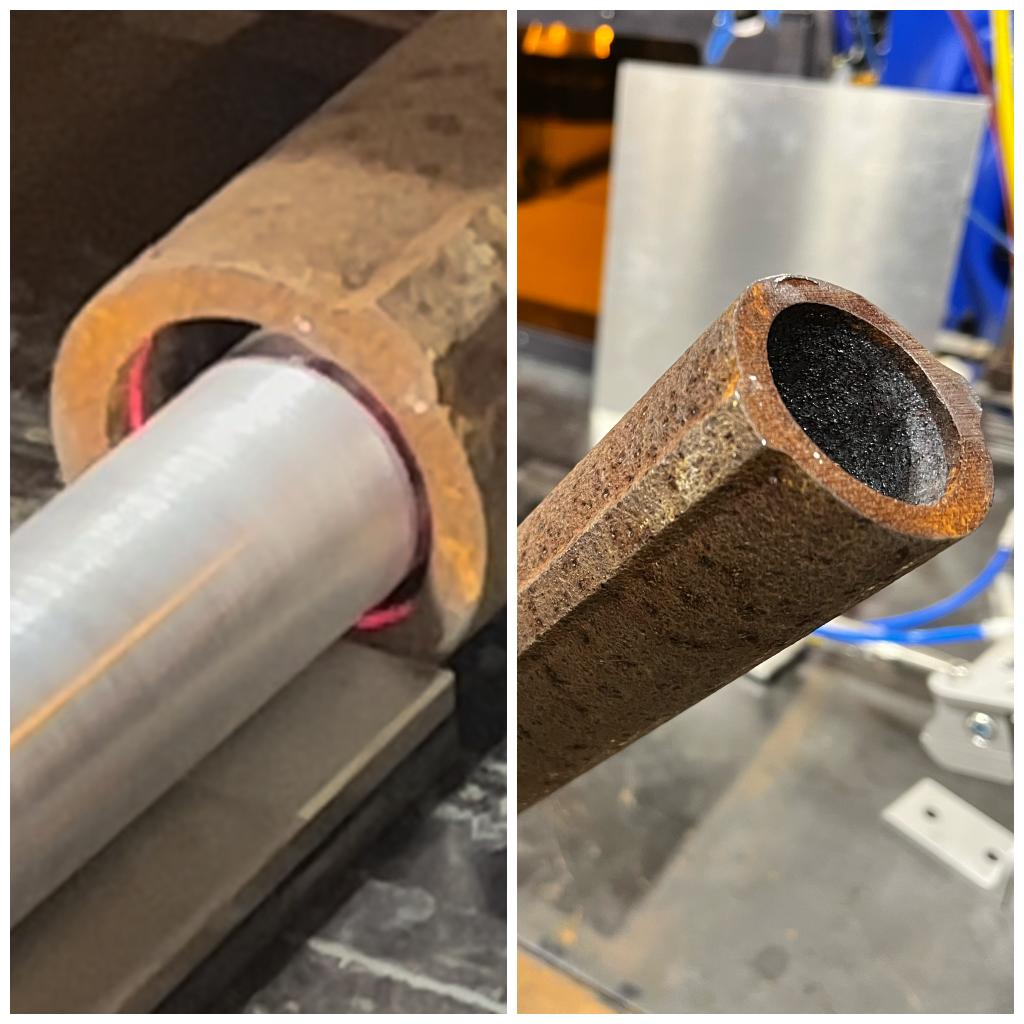

Common Problems.

Here are some common problems faced by industries due to corrosion and

contamination buildups in tubes and pipes

Reduced Efficiency

Corrosion and contamination inside tubes and pipes can restrict the flow of fluids or gases, leading to decreased efficiency and performance. This can result in lower productivity and increased energy consumption.

Safety Hazards

Corroded or contaminated pipes pose safety risks in industrial settings. They can result in leaks, spills, or hazardous material exposures, potentially leading to accidents, injuries, or environmental damage.

Maintenance Costs

Regular maintenance, repair, and replacement of corroded or contaminated pipes can be expensive and time-consuming. The accumulation of rust and contaminants necessitates frequent cleaning, inspection, and maintenance procedures.

Compliance Issues

Industries are often required to adhere to strict regulations and standards related to safety, environmental protection, and product quality. Corrosion and contamination in pipes can lead to non-compliance, resulting in penalties, legal consequences, and damage to reputation.

damage to the parent metal

Most of these techniques essentially do not care whether you are treating the deposit or the original metal itself. And it can cause material wastage and damage, and overtime this leads to a reduced lifetime of the tubes or pipes. Because these conventional techniques in essence are agnostic to what they are cleaning, and if there is no deposit, it will end up hurting the parent material.

The Solution.

Features.

01

Precision

Laser technology precisely targets and removes rust and contaminants from tubes and pipes, ensuring thorough cleaning and optimal performance

02

Gentle Cleaning

The non-abrasive approach of laser rust removal or cleaning effectively removes rust and contamination without causing damage to the treated surfaces, ensuring safe and reliable operation

03

Versatile Use

Laser cleaning systems offer versatile applications, adapting to various types of tubes and pipes internal and external surfaces in different industries, providing efficient cleaning solutions for a wide range of systems

04

Environmental

Laser technology eliminates the need for chemicals or solvents in the cleaning process. Unlike some traditional cleaning methods, this is an environmentally friendly, dry, contactless cleaning process that produces no waste or emissions

05

EPA, ESG, OSHA

Significant push for adopting laser cleaning technology from manufacturers in multiple industries. Laser-blasting technology being acknowledged by industries professionals as they prepare for the potential adoption of laser technology

06