- Sustainability And Quality

- Fast Delivery

- Leading Through Innovation

- Patented Technologies

- Laser Engineering NPD Team

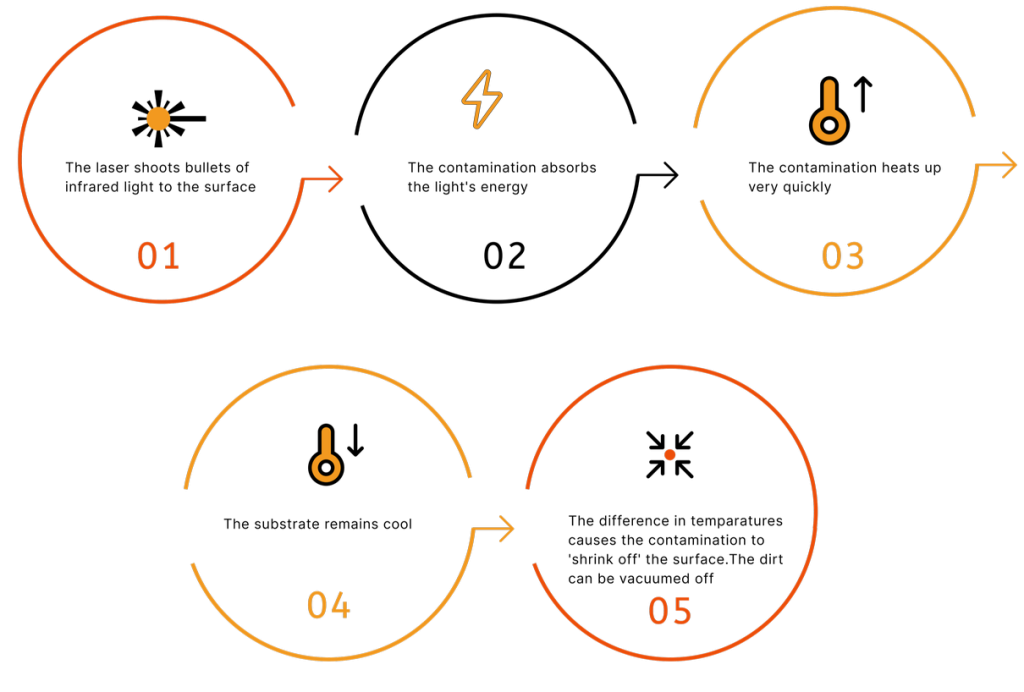

Laser cleaning is a remote process that enables precision material removal, virtually eliminating damage to the underlying material.

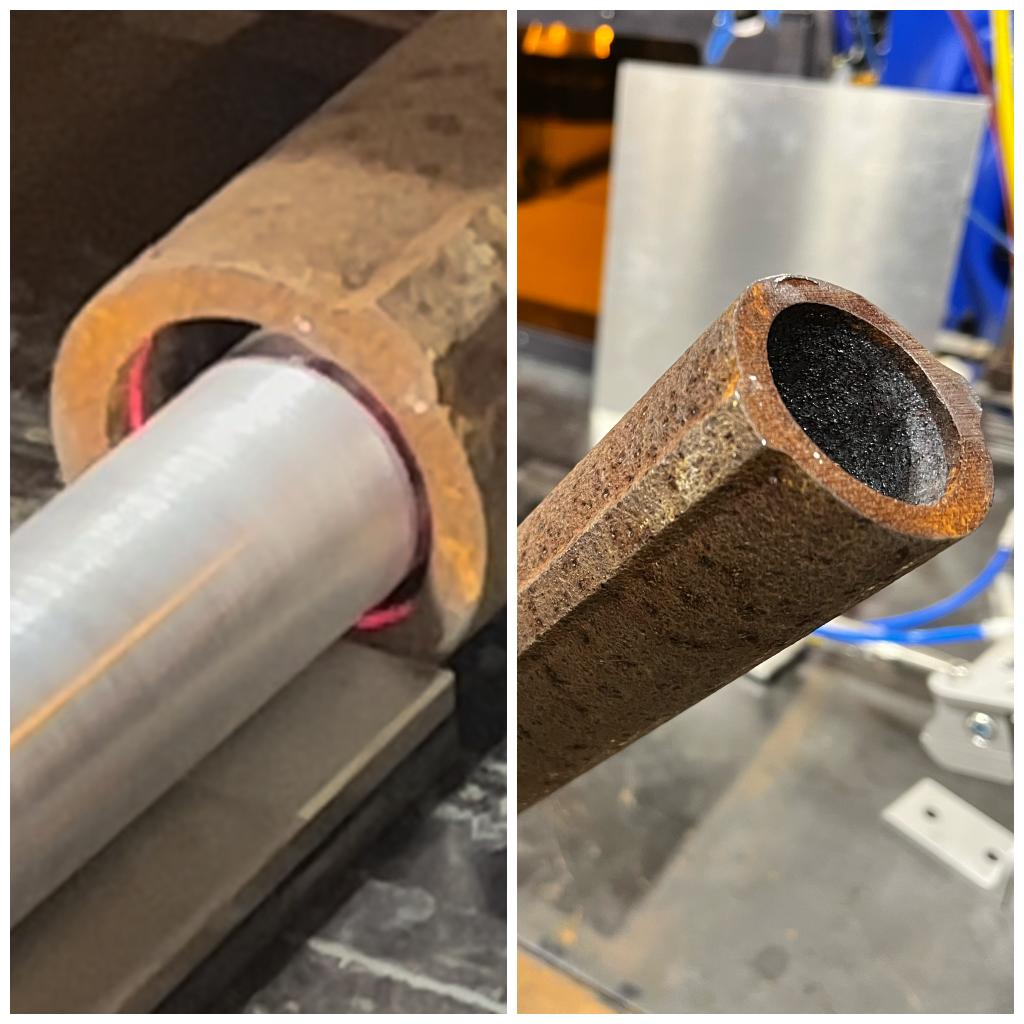

Revolutionary tubes & pipes cleaning tool with our world’s first and patented laser technology. Laser can ablate clean tubes & pipes internal surfaces, up to 1 inch ID. Say goodbye to all conventional cleaning methods that are time-consuming, inefficient, waste generating, and hazardous.

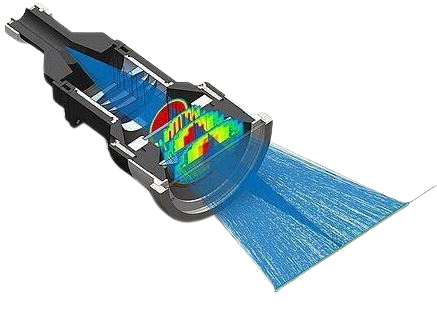

Revolutionize your industrial cleaning process with our powerful handheld fiber laser blasting systems. Our cutting-edge technology delivers laser precision cleaning at 1kW, 2kW, 3kW, and 4kW power levels, all custom designed and integrated in-house, providing unmatched efficiency and effectiveness.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Maecenas posuere accumsan laoreet. Donec id sem quam. Mauris pulvinar magna nec odio iaculis tristique.

Nullam commodo consequat augue, id cursus nisl. Duis lobortis sodales velit, quis maximus urna commodo ultricies. Nam hendrerit dui erat. Donec eu consequat augue. Mauris quis elit dignissim, lacinia odio lacinia, eleifend lorem.

Laser cleaning is a remote process that enables precision material removal, virtually eliminating damage to the underlying material.

Laser cleaning is highly precise and targets only the area to be cleaned, eliminating additional steps like masking.

Laser cleaning is a highly energy efficient process that requires no cleaning media, dramatically reducing material handling requirements and process waste.

Laser cleaning technology is healthier and safer for operators than legacy abrasive cleaning methods. Laser cleaning technology also eliminates the need for chemicals or solvents that other cleaning methods like chemical peeling utilize. It is safer cleaning method that eliminates the costs associated with disposing hazardous or toxic material. Due to these fundamental differences, there has been a strong push from agencies like the OSHA for stricter regulations, leading to an increase in the adoption of laser cleaning technology among numerous industries in the recent years.

INV systems support adjustable power settings ranging from 1W to 4kW for different cleaning applications and customer needs.

It is effective on metals such as Carbon Steel, Aluminum, and Stainless Steel, as well as surfaces with rust, paint, coatings, oxides, or grime and plenty other types of contaminations.

Micro-level precision, allowing for controlled and selective removal without damaging underlying materials.

Approximately 3 ft to ensure safety, (Customized cleaning distances are available) with optimal beam focus and efficiency.

Yes, laser cleaning can modify surface roughness if needed to enhance coating adhesion. By adjusting parameters like average power level, pulsing frequency, and scanning speed, the system can create an ideal surface profile for paint, coatings, or bonding applications.

Yes, a stable power supply within the specified voltage range is critical.

While the system can function in moderate humidity, it is recommended to avoid excessive moisture to prevent condensation-related issues inside the optical system.

O&G

Nuclear

Medical

Food & Beverage

Military

General Manufacturing